My Asset View

Cloud Application, Electron Desktop Application

Project Brief

MyAssetView software allows thermographers to use thermal imaging cameras to survey assets for thermal trends to catch faults before they occur. By doing so it is possible to avoid production downtime from unexpected failure causing damage or fire, staff injury and fatalities.

This software can track an asset over its lifespan so that each time it is inspected thermal trends can be analysed to determine if there is a potential point of failure.

Offline sync allows technicians to work offline while in remote or difficult to access locations where stable internet connections are not available.

- Client:My Asset View

- Date:2017

- Industry:Thermography

- Technologies:Laravel, Vue, Electron

- Site:thermoscan.com.au

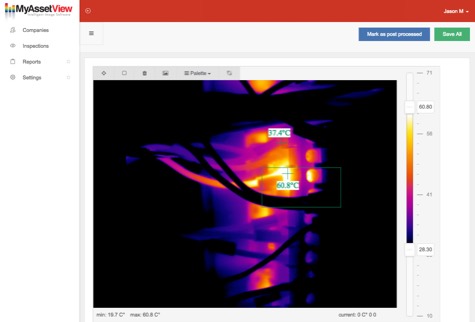

Thermal Data Processing

Analysis of the thermal data allows the user to identify multiple hotspots within an image.

After multiple inspections a baseline trend can be identified to ensure any changes over time can be monitored.

Electron Application

The Electron application allows technicians to load the My Asset View software onto a tablet such as a Microsoft Surface to take on site. Whilst onsite the technician can sync their location offline to allow them to make their updates to assets quickly and easily before sending the data back to the cloud server once they have a stable internet connection.

Have any questions? Get in touch today with one of our digital strategists.